Round Grates – Rare Earth Storch Metal Separation |

Round Grates – Rare Earth

|

|

|

|

||

| Round Grates – Rare Earth |

Features |

Benefits |

Free Product Testing & Magnet Audits

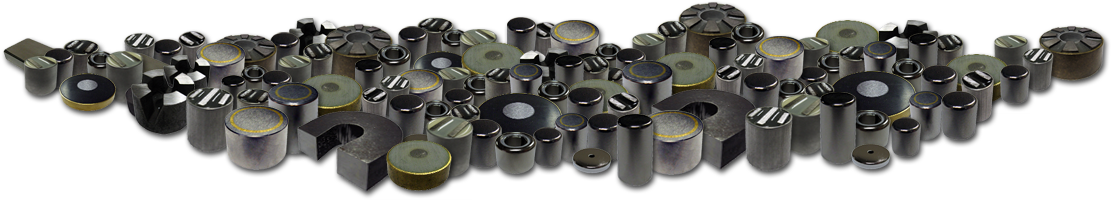

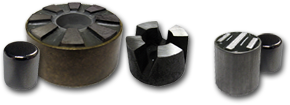

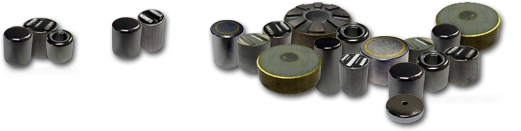

Remove tramp iron metal scrap contamination and fine particles from all types of processing lines. Storch Magnetics offers the greatest magnetic grate options: 9 standard styles & specials – Rare Earth High Energy Grade 52 Mgo, Ceramic 8, Alnico 1000 F High Temp

Contact Storch for: Free – Application – Assistance to ensure you get the best performance & prevention of product contamination, machinery damage, loss of production, and to reduce unnecessary maintenance and repair costs.

Engineered and Manufactured from Storch High Strength Magnetic Tubes (MT-Series) with seamless liquid tight welds.

Call 1-800-338-3482 for Proper Grate Magnet Selection

Grate Magnet Features:

Grate Magnet Features:

- Storch Tube Magnets on 2″ centers in rugged grid assembly

- Ceramic 8, Rare Earth, or Alnico, meets/exceeds IMA Standards

- Single or Double Row Magnet Grates

- Min. 1/8″ Durable Protective Stainless Steel Stringers/Frames

- Configured to suit from 4″ round, square, rectangular up to 60″

- Standard wipe/blow off cleaning

- Optional easy clean or automated pneumatic clean models to suit.

Remove tramp and fine particles from all types of dry processing lines with Storch Magnetic Grates. These grates entrap and separate ferrous particles, preventing damage to machinery, contamination of product, and excess repair and maintenance. Powerful permanent tube magnet cartridges are encased in stainless steel frames and can be installed in steep, sloped, or irregular shaped hoppers, floor dump openings, closed vertical or horizontal chutes, and flow ducts.

Magnet Housings with Double, Triple & Four Row Drawer Grates

Magnet Housings with Double, Triple & Four Row Drawer Grates

Magnetic Housing Features:

- Storch Tube Magnets and Grate Magnets

- Stainless Steel Construction

- Easy wipe/blow off clean magnet

- Optional easy clean no magnet contact

- Optional automated pneumatic clean to suit

- Optional Lexan see through drawer front

- Optional Inlet dump tube, liquid port, purge spout.

Protect machinery from ferrous fragments and reduce operating costs by trapping contaminant in Storch’s high product flow In-Line Magnetic Housings. Located over orifices, in spout systems, or below hoppers, the process material is filtered through a chamber where the undesirable contaminant is trapped by the rows of magnetic cartridges.

People who visited this page also visited these Storch Magnetics pages:

Inline Liquid Finger Trap

Inline Plate Trap

Micro Mag