Chip Coolant Separators Storch Metal Separation |

Chip Coolant Separators

|

|

|

|

||

| Magnetic Chip Coolant Separator |

Features |

Benefits |

- High Energy Rare Earth Magnetic Drum Separator provides 5 ½ times Strength over

- standard ferrite ceramic drums available.

- 100% More Magnetic Gauss at furthest coolant flow under precision formed weir.

- 98% Separation Efficiency down to 10-20 Micron.

- Most Dependable Non-Disposable maintenance free Magnetic Pre-Filter Available.

- Hi-Intensity rugged Industrial Magnetic Drum built to Outperform & Outlast!

|

|

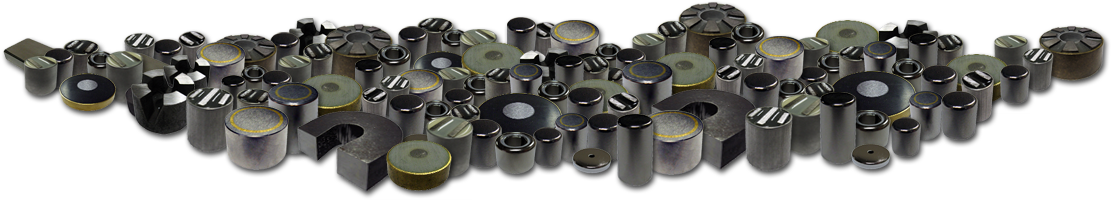

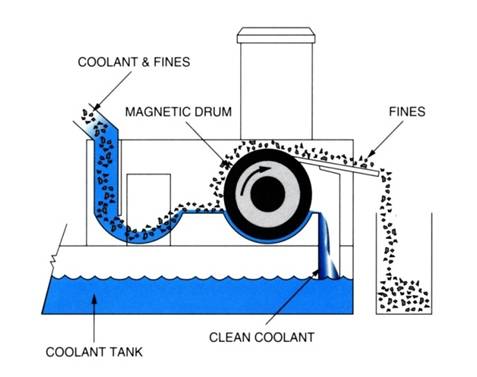

Keep gravity liquid flows, coolants, wash systems and more….CLEAN – with Storch Hi-Energy Rare Earth Self-Cleaning Magnetic Chip Coolant Separators (CCS – Series) or Specials Built-to-Suit your unique or larger central applications. Storch CCS-Series nearly eliminates costs of paper filter media, labor to change/clean filters, tanks and fluid lines. Your Liquid or Coolant is directed into the powerful permanent rare earth industrial magnetic rotating drum face, resulting in a magnetic cake screen of ferrous, and trapped non-ferrous when operated in optional Index mode.

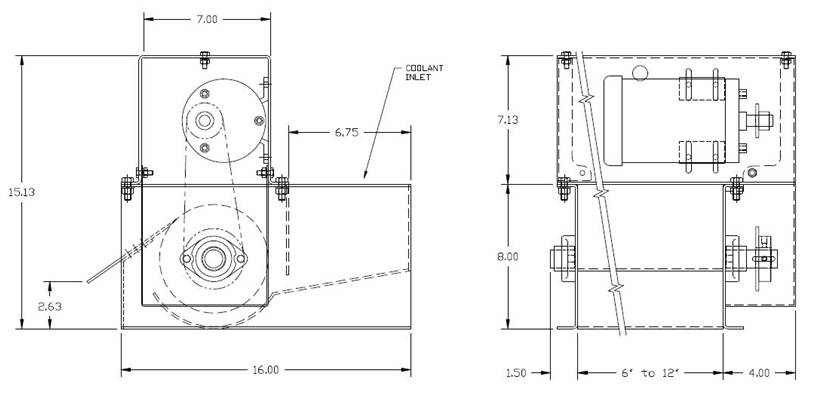

Standard Capacities Range from 10 GPM to 135 GPM and Storch has manufactured unique and custom sizes to handle up to 4,000 GPM. Reference back for standard sizes & call for specials.

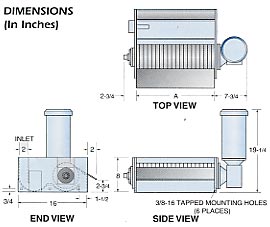

Chip Coolant Separators (CCS)

|

|

Options:

- Conveyors

- Tanks

- Pumps & Valves

Surge Break Tanks

- Side Drives

- Double Reduction

- Motor Brand Preference

- Indexing Controls

Secondary Finish Filters

Keep Cutting Coolants Clean with Storch Self-Cleaning Magnetic Chip Coolant Separators while Reducing CostsRemove ferrous and non-ferrous particles easily and efficiently. The coolant is directed into a powerful wet industrial magnetic drum separator, which attracts the ferrous particles onto the drum magnet face, the resulting cake also traps the non-ferrous contaminants when operating in index mode.

|

|

|

|

|

Continuous Rotating Magnetic Drum |

Indexing Magnetic Drum |

|

|

|

|

|

Model

|

Dimension ‘A’ inches

|

Flow Rate Capacity(GPM) | |||

| Water Soluable | Mineral oil(100 ssu) | ||||

| Indexing | Continuous | Indexing | Continuous | ||

|

G200-060

|

6 | 15 | 23 | 9 | 14 |

|

G200-120

|

12 | 30 | 45 | 18 | 27 |

|

G200-180

|

18 | 45 | 68 | 27 | 41 |

|

G200-240

|

24 | 60 | 90 | 36 | 54 |

|

G200-300

|

30 | 75 | 113 | 45 | 68 |

|

G200-360

|

36 | 90 | 135 | 54 | 81 |

Chip Coolant Separator FiltersChip Coolant separators are specifically designed* to integrate with chip-producing machine tools and grinding machines, or as part of a central coolant system. Coolant Separators Provide:

|

|

People who visited this page also visited these Storch Magnetics pages:

Chip Coolant Separators

Magnetic Tubes

Wet Drum Separators