Request A Quote

For information or a quote, please contact us:

Toll Free: 800.959.0047 • Phone: 734.591.2200

Email: sales@storchmagnetics.com

Chip Conveyors

Storch conveyors specialize in conveying ferrous and non-ferrous chips, turnings, punch-outs, slugs, and finished parts. Our conveyors are also ideal for fasteners, small assembly components, laser trim stock, and more.

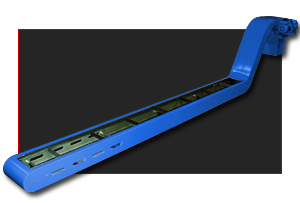

Magnetic Slide Conveyor

Applications: Conventional & CNC Machining, CNC Turning, Vertical & horizontal milling, Metal Stamping, Cold Heading, Parts Feeding, Central Collection, Metal Processing

Ideal for ferrous materials: fasteners, nuts, bolts, washers, screws, small assembly components, laser trim stock, small turnings, chips, punch-outs, slugs, finished parts.

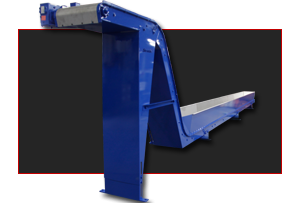

Steel Hinge Belt Conveyor

Applications: CNC Machining, CNC Turning, Vertical & Horizontal Milling, Light-Medium Gauge Metal Stamping, Cold Heading, Parts Feeding, Central Scrap Collection

Ideal for small to large parts, fasteners & scrap handling, light to heavy chip handling transfers, and applications that create stringers and bird’s-nests.

Drag-Flight Conveyor

Applications: CNC Machining, Grinding & Lapping, CNC Turning, Vertical & Horizontal Milling, Light-Medium Gauge & Central Scrap Collection

Ideal for Single Station, Central or In-Floor Systems and OEM integration to convey wet or dry ferrous and aluminum machining chips. Drag-Flight Conveyors can be configured with or without integrated separation or filtration systems and are engineered to a particular application for a machine’s size and chip/scrap removal rates.

DragOn™ Conveyor

Applications: Paper-bed media filters, CNC machining, grinding and lapping, CNC turning, vertical and horizontal milling

Ideal for separating and conveying chips, fines, and swarf down to 5-10 Micron – 98% efficiency with NO paper Media needed*. In addition to being one of the best options for ferrous filtration, The DragOn™ can handle non-ferrous chips with a small drop plate to bypass the magnetic separator.

* Contaminated coolant containing cast iron and/or steel chips, fines, or swarf has an effective separation of 98% down to 15-20 microns. Further separation occurs down to 5-10 microns at various lower percentages based on ferrous metal grade being machined, coolant or oil type and GPM rate.