Electric Shakers – Tsunami Storch Material Handling |

Belt Conveyors – Magnetic

Belt Conveyors – Non Magnetic

Pneumatic Shaker – Air Quake

Electric Shakers – Tsunami

Scrap & Part Transporters, Metal Transporters,Vibratory Transporters & Conveyors

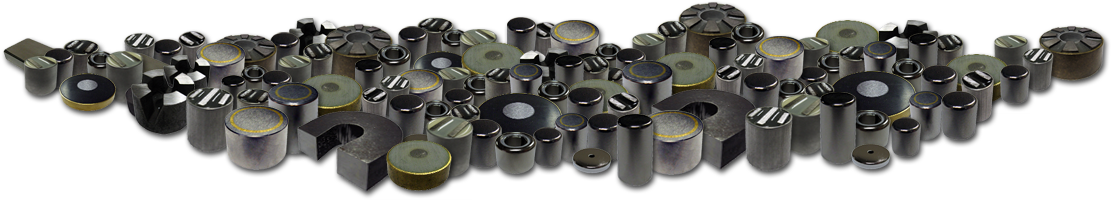

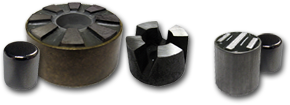

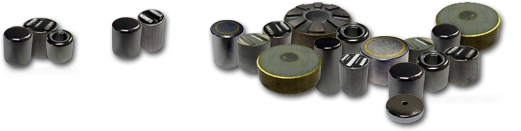

Storch offers the widest variety of Shakers a.k.a. Transporters available in the market today to fit your requirements. You have two choices of power sources and the future cost of maintaining your long term investment can be drastically different in the end. The two options from Storch are Pneumatic (AirQUAKETM) and Electric (TSUNAMI) Powered drives. Each respective Shaker Drive technology from Storch simply uses only one or the other, air, or single phase 110volt electricity. With no costly belts to wear or tear, it should be no surprise why both types of drives have become the most successful replacement of low profile belted conveyors over the last decade. The drives are very adaptable to all sorts of applications and with the quick fabrication of a custom metal tray, they are guarantee to fit your specific application without compromise. Using one of these shaker drives along with some simple training and a little creativity on your part, all kinds of secondary operations can take place during conveying as well as: sorting, screening, separation of coolant from parts, as well as separation of ferrous and non ferrous medias via additional magnetic equipment just to name a few. Contact a Storch shaker expert for more ideas about your specific application.

Storch offers the widest variety of Shakers a.k.a. Transporters available in the market today to fit your requirements. You have two choices of power sources and the future cost of maintaining your long term investment can be drastically different in the end. The two options from Storch are Pneumatic (AirQUAKETM) and Electric (TSUNAMI) Powered drives. Each respective Shaker Drive technology from Storch simply uses only one or the other, air, or single phase 110volt electricity. With no costly belts to wear or tear, it should be no surprise why both types of drives have become the most successful replacement of low profile belted conveyors over the last decade. The drives are very adaptable to all sorts of applications and with the quick fabrication of a custom metal tray, they are guarantee to fit your specific application without compromise. Using one of these shaker drives along with some simple training and a little creativity on your part, all kinds of secondary operations can take place during conveying as well as: sorting, screening, separation of coolant from parts, as well as separation of ferrous and non ferrous medias via additional magnetic equipment just to name a few. Contact a Storch shaker expert for more ideas about your specific application.

BENEFITS

- Near Silent Operation!

- Most compact Electric Shakers on the market!

- No compressed air required

- Simple on/off power switch with built in breaker

- Can be plugged directly into press controls with 110volt single phase outputs

- Minimal electricity costs; operates for only pennies per day

- No spare parts required & Never needs maintenance

- Runs on 110V single phase with included standard three-prong plug, Plug and play operation!

OPTIONAL– MULTI PAN TURNKEY SYSTEMS UP TO 14’ WIDE

Features:

- Engineered for rugged, high-volume applications

- Made in U.S.A.

- Quiet operation

- Pp to 20 fpm part movement speed

- Simple on-off power switch/ breaker

- Ties into press controls for auto startup and shut down

- Handles up to a 7’ cross bar

(for cross bars over 8’ we recommend a rack and pinion)

- Runs on 110V standard three-prong plug

- Limited one-year manufacturer’s warranty

Specifications:

- Measurement: 6.25” H x 27.25” W x 14.5” D

- Pan weight maximum: 200 lbs.

- Power: 115 VAC, single phase

- Options: T-slot motor mounts; rack and pinion system; custom trays; aluminum extrusions cut to length; height adjustable cart; quick release brackets

Storch’s heavy duty TES-200 Tsunami Electric Shaker uses a standard 110V, three-prong AC electrically driven motor. Its silent operation and maintenance-free reliability make the most versatile and affordable part transferring machine on the market. With a 200 lb. tray capacity, up to 20 FPM part movement speed, a simple on-off reset breaker, and accessibility to tie into your press controls for automatic startup and shut down, the TES-200 is the only part transfer unit you’ll ever need. Do you require a unit that can exceed the TES-200’s 14-foot capability when used with a rack-and-pinion system? The MTES-200 is universally compatible with other TES-200 units, meaning you can run two or more units together simultaneously to meet your objectives. Better yet, the TES-200 can use up to a 6’ cross bar without jeopardizing the included one-year warranty.Tell us how we may help!