Magnetic Sheet Fanner (Sheet Separator)

Request A Quote

Tell us how we may help! For information or a quote, please contact us:

Tell us how we may help! For information or a quote, please contact us:

Toll Free: 800.959.0047 • Phone: 734.591.2200

Email: sales@storchmagnetics.com

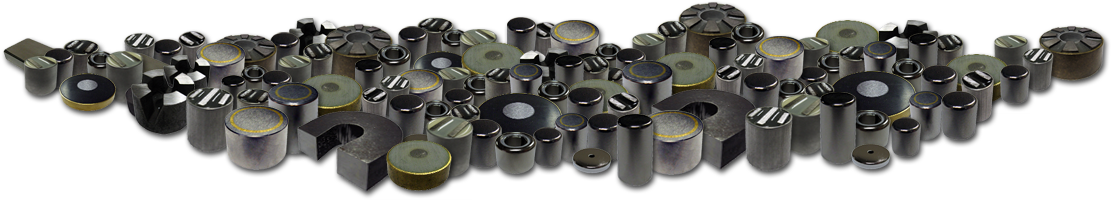

Magnetic Sheet Fanners (Sheet Separators) – Series SF

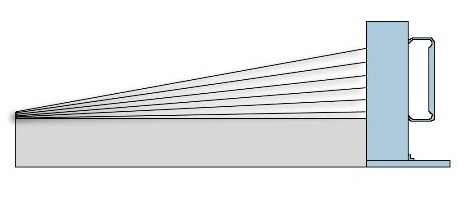

Storch Magnetic Sheet Separators induce a magnetic field to the ferrous steel sheet stack. The induced magnetic field creates like magnetic polarity between the top and second sheets. Like magnetic polarity repels one another resulting in the top sheet pushing away from the lower sheet.

Storch Magnetic Sheet Separators increase efficiency, production and safety while reducing the handling problems of stacked sheet steels. Magnetic Sheet Separators reduce marring, double-blanking and the need for prying sheet stock apart.

In addition to our standard line of Magnetic Sheet Separators, Storch also offers specially designed Magnetic Sheet Separators to suit your specific application. Rare Earth Magnetic Sheet Separators are also available upon request.

Features

- Lifetime Guarantee of Permanent Magnet Strength

- Less than 1% magnetic loss in 100 years

- Durable 304 Stainless Steel construction standard

- Finest of Magnetic Materials used meeting IMA/MMPA standards

- Can be applied to manual as well as robotic press-feeding systems

- Lift handle and counter-balanced base for stability

Benefits

- Increase Safety, Productivity, Uptime & Profitability by reducing double-blanking

- Reduce scrap loss

- Reduce worker fatigue

Magnetic Sheet Separator Performance:

Performance chart was developed by testing of standard mill-run 16” x 24” mild steel sheet. This chart was developed around common sheet sizes. Standard Storch sheet fanners can handle 30 gage to 9 gage sheet metal applications.

Consult Storch Magnetics with applications beyond this range.

| Chart represents typical distance between fanned sheets (“) |

| Sheet # | 22 gauge | 16 gauge | 13 gauge |

|---|---|---|---|

| Series 1 Separators | |||

| 1 | 1/2 | 3/8 | 1/4 |

| 2 | 3/16 | 3/32 | 1/16 |

| 3 | 1/8 | 1/16 | – |

| 4 | 1/16 | 1/16 | – |

| Series 2 Separators | |||

| 1 | 11/16 | 5/8 | 7/16 |

| 2 | 7/16 | 5/16 | 1/8 |

| 3 | 5/16 | 1/8 | 1/16 |

| 4 | 3/16 | 1/16 | – |

| Series 3 Separators | |||

| 1 | 3/4 | 11/16 | 5/8 |

| 2 | 1/2 | 1/4 | 1/8 |

| 3 | 5/16 | 3/32 | 1/16 |

| 4 | 3/16 | 1/16 | 1/16 |

For highly oiled sheets, multiple Magnetic Sheet Separators may be required.

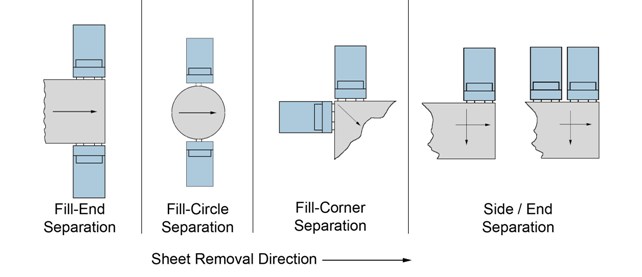

Magnetic Sheet Separator Typical Placements:

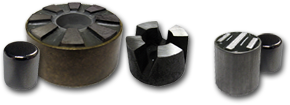

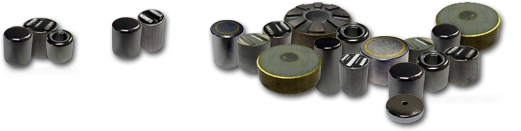

Magnetic Sheet Separators (SF Series 1-3)

For Light, Medium or Heavy Gage Steel

| Part Number | A (“) | B (“) | C (“) | D (“) |

|---|---|---|---|---|

| Series 1 – For Light Gage Steel | ||||

| SF1-1427 | 7.25 | 5.25 | 1.75 | 5 |

| SF1-1428 | 10.25 | 5.25 | 1.75 | 5 |

| SF1-1429 | 13.25 | 5.25 | 1.75 | 5 |

| SF1-1430 | 16.25 | 5.25 | 1.75 | 5 |

| Series 2 – For Medium Gage Steel | ||||

| SF2-1431 | 10.25 | 6.25 | 2.75 | 8 |

| SF2-1432 | 13.25 | 6.25 | 2.75 | 8 |

| SF2-1433 | 16.25 | 6.25 | 2.75 | 8 |

| SF2-1434 | 19.25 | 6.25 | 2.75 | 8 |

| Series 3 – For Heavy Gage Steel | ||||

| SF3-1435 | 10.25 | 6.25 | 3.75 | 10 |

| SF3-1436 | 13.25 | 6.25 | 3.75 | 10 |

| SF3-1437 | 16.25 | 6.25 | 3.75 | 10 |

People who visited this page also visited these Storch Material Handling pages: