Hump Magnets Storch Metal Separation |

Hump Magnets

|

|

|

|

|

||

| Hump Magnets |

Features

|

Benefits

|

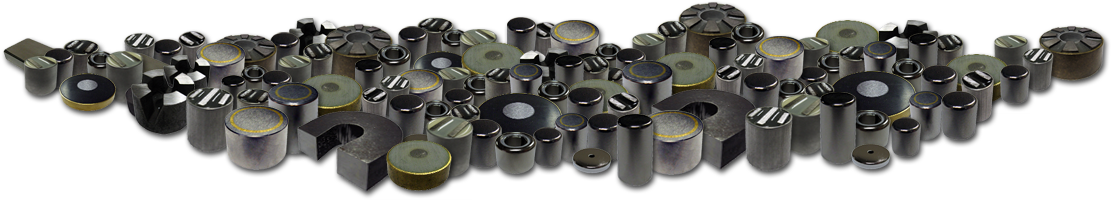

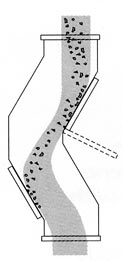

Hump, Half Hump, and 90° Elbow Magnet Separators

Since most applications are unique Storch Manufactures Hump Magnets to your exact requirements and does not restrict you to a few standard sizes or configurations. Please contact Storch Engineering to assist you in designing the most effective Hump Magnet Separator housing to your application.

Since most applications are unique Storch Manufactures Hump Magnets to your exact requirements and does not restrict you to a few standard sizes or configurations. Please contact Storch Engineering to assist you in designing the most effective Hump Magnet Separator housing to your application.

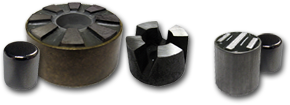

Hump Magnets are very powerful and used in protecting your handling facilities, product and processing equipment from tramp iron hazards-fine ferrous fragments, shavings, nuts, bolts, and mavericks such as wrenches, screwdrivers and hammers from even free-flowing, clumping or bridging type materials. Effective tramp metal recovery with dog-leg configuration forces product flow to contact the plate magnets directly. Simple cleaning: swing plate magnet from housing to wipe away contaminated metal recovery away.

Provided with inlet adapter to match your existing tube or pipe to carry dry material across the plate magnet penetrating field entrapping tramp metal while product transitions back to your chute. Material flow is stopped for tramp metal recovery from hinged Plate Magnet or Bullet Magnet.

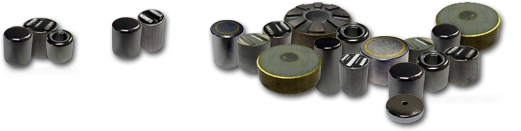

Twin Plate Deep Reach Extractor Magnet Separator Housings

Exceptional where vertical chute space is limited, high product flows exist and metal removal/recovery is effectively needed. Top of housing has a diverter flowing materials across deep reach twin plate extractor magnets that collect tramp metal until magnets are swung out to remove tramp metal. Used in plastic, food, grain, feed, machinery like pelletizers, packaging, hammer mills, and other processing.

People who visited this page also visited these Storch Metal Separation pages:

Hump Magnets

Crossbelt Separators

Suspended Plate Magnets